The model KSFI Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element. This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFI flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either vertically or horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SS, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 15mm to 600mm and available upon request. Standard flanges are ANSI 150lb and other connections and size are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

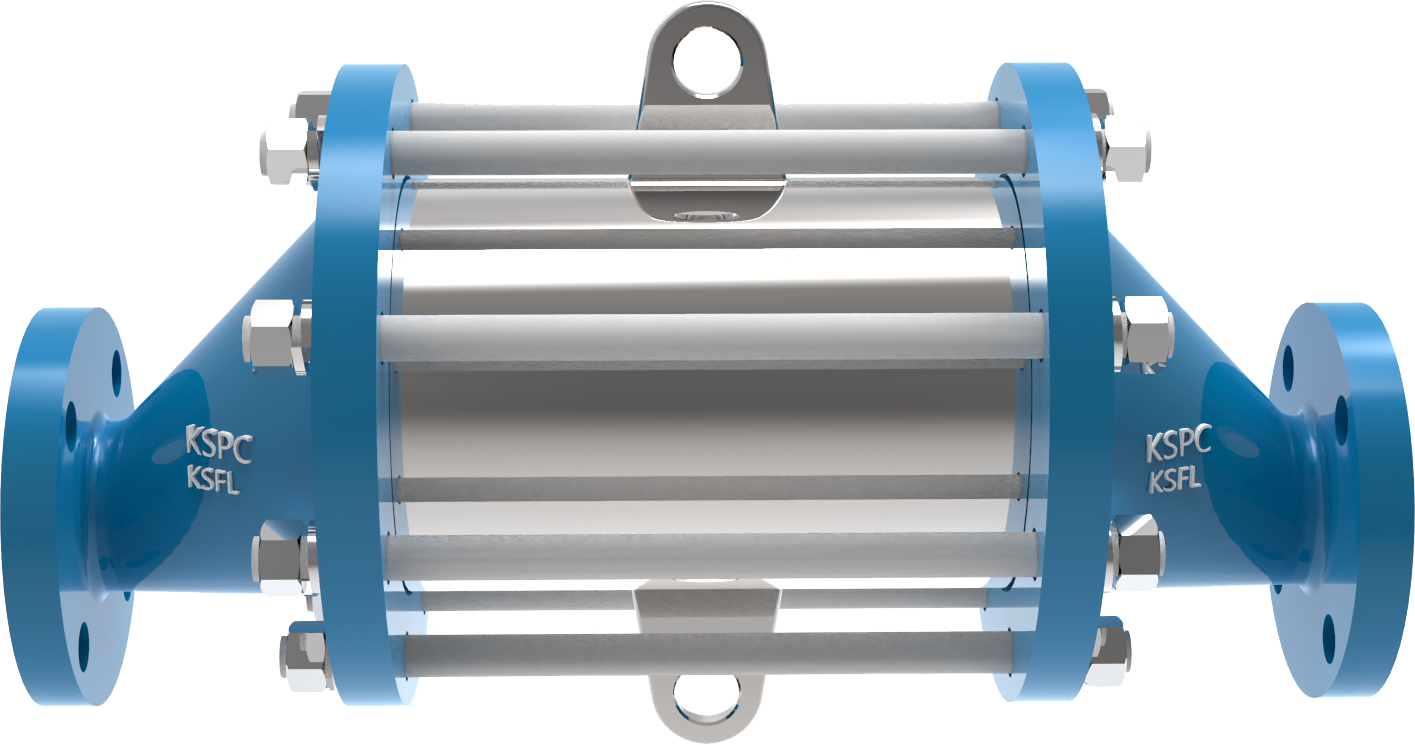

The model KSFH Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

Additionally All most of size shall be approved FM (Factory Mutual).

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element.

This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFH flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either vertically or horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size 2” / 50A to 12” / DN 300.

Upon request, it can be obtained for higher pressure and higher temperature with special approval

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SSss, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 50mm to 300mm. Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

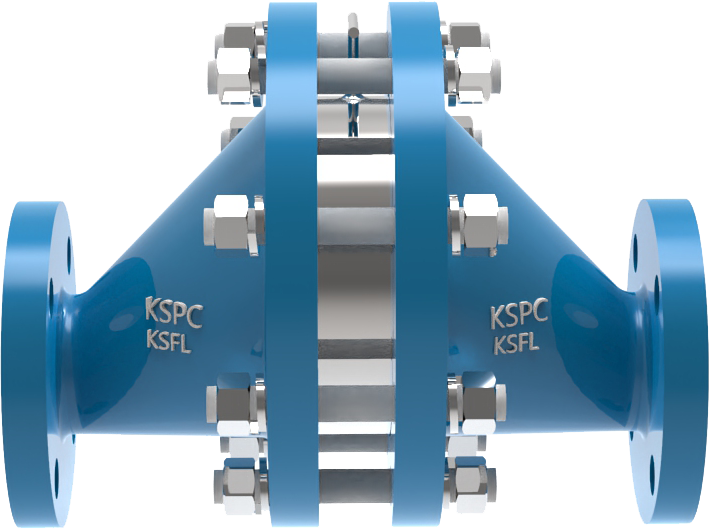

The model KSFL Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element.

This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFL flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size 2” / 50A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SS, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 25mm to 600mm. Standard flanges are ANSI 150lb and other connections & size are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 90 deg C / 140 deg F and Maximum allowable operating pressure up to 1.2 bar abs from size ½” / 15A to 6” / DN 150 and up to 1.1 bar abs from size 8” / DN200 to 16” / DN 400. Upon request, it can be obtained for higher pressure and higher temperatrue with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 15mm to 300mm as Standard and upon request, it can be obtained for higher size.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The KSFE unit gives the protection needed. For size 4” and under after ignition of the out flowing gases a fusible element melts, the spring loaded cover automatically opens and the full surface of the flame arrester is exposed so that the flame arrester element will not attain the ignition temperature through heat absorption.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 90 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 20” / DN 500. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

Housing construction are Aluminium, Cast Iron, Cast Steel, 304SS, and 316LSS. Hood construction is stainless steel and the element is 316LSS.

Sizes are from 20mm through to 500mm.

Cast iron and cast steel units are epoxy coated both inside and outside.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

FEATURES / BENEFITS

Flame Trap A’ssy of KSPC makes no difference though it is installed in line of horizontality or perpendicularity. Fuse has an element which is made of metal, and to be melted easy. So it can intercept flame within 15 seconds at 260 deg F (=127 deg C)

You can see the position of valve disc stem at outside though heat resisting plate glass, so you can confirm whether valve is opened or closed. Also disassembly and cleaning of flame element is convenient and we can repair fast and it doesn’t need disassembly by exchange.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.