The model KSEPKJ is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents. These vents provide the capacity to meet API standard 2000 for emergency venting due to fi re exposure when properly sized. These covers also provide quick easy access for tank inspection and maintenance.

The model KSEPKJ is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents. These vents provide the capacity to meet API standard 2000 for emergency venting due to fi re exposure when properly sized. These covers also provide quick easy access for tank inspection and maintenance.

The model KSEPW is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents. These vents provide the capacity to meet API standard 2000 for emergency venting due to fi re exposure when properly sized. And it provides quick easy access for tank inspection and maintenance. And also designed to be Cushioned Air Seating, Tefl on(FEP+PTFE) diaphragm are standard. The excessive pressure over 75% of set point builds up to 90% of set point, the Liquid (Silicon oil) catch up the Leakage and meet bubble tight (no leakage) at 90% of set pressure. It is designed to be self closing under normal operation by inside Guide and the restraining cables to connect the Cover A'ssy and Flange.

The model KSEPW is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents. These vents provide the capacity to meet API standard 2000 for emergency venting due to fi re exposure when properly sized. And it provides quick easy access for tank inspection and maintenance.

And also designed to be Cushioned Air Seating, Tefl on(FEP+PTFE) diaphragm are standard. The excessive pressure over 75% of set point builds up to 90% of set point, the Liquid (Silicon oil) catch up the Leakage and meet bubble tight (no leakage) at 90% of set pressure. It is designed to be self closing under normal operation by inside Guide and the restraining cables to connect the Cover A'ssy and Flange.

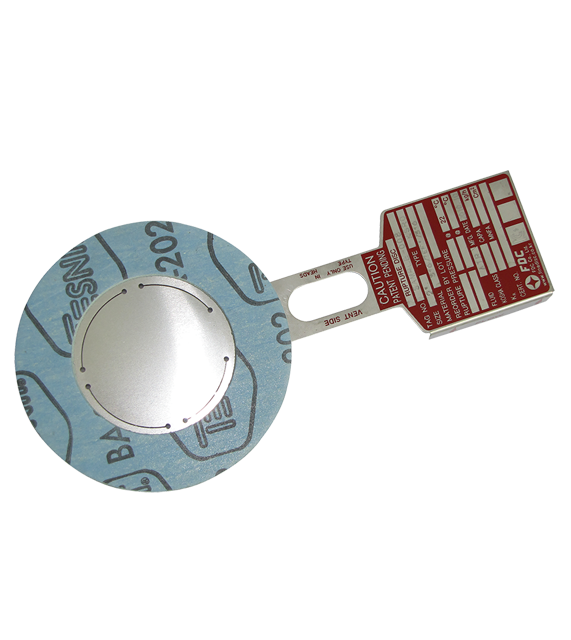

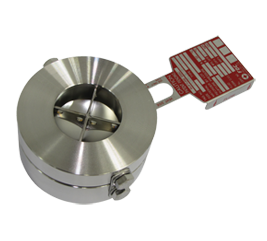

Situations that demand a Rupture Disc

• In case there is any concern that there can be an abrupt rise in pressure that cannot be endured by a spring type safety valve.

• In case there is any concern that fixtures generated by the operation state may damage the operation function of other safety materials owing to excessive pressure.

• In case the leakage of oil reserved in a tank from a safety device is not permitted during an operation.

• In case there is a need to have a protective device in preparation for a container and pipe that reserves or produces oil of a strong corrosive nature.

• In case of handling or reserving materials that are likely to undergo a synthetic reaction.

• In case there is a possibility that an excessively high or low temperature in the operational environment might inhibit the operation of a safety valve.

Situations that demand a Rupture Disc

• In case there is any concern that there can be an abrupt rise in pressure that cannot be endured by a spring type safety valve.

• In case there is any concern that fixtures generated by the operation state may damage the operation function of other safety materials owing to excessive pressure.

• In case the leakage of oil reserved in a tank from a safety device is not permitted during an operation.

• In case there is a need to have a protective device in preparation for a container and pipe that reserves or produces oil of a strong corrosive nature.

• In case of handling or reserving materials that are likely to undergo a synthetic reaction.

• In case there is a possibility that an excessively high or low temperature in the operational environment might inhibit the operation of a safety valve.

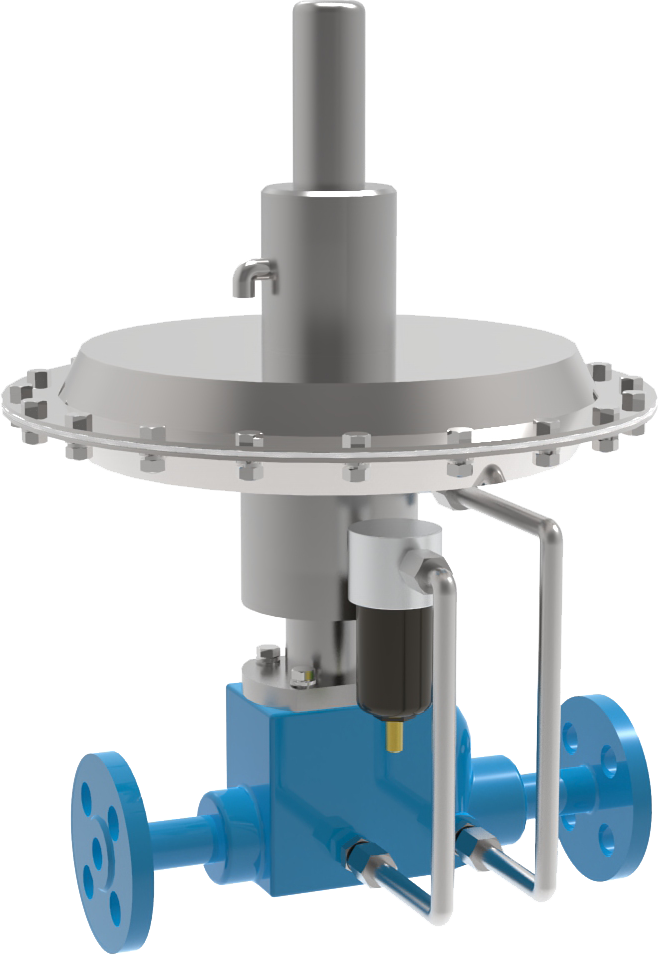

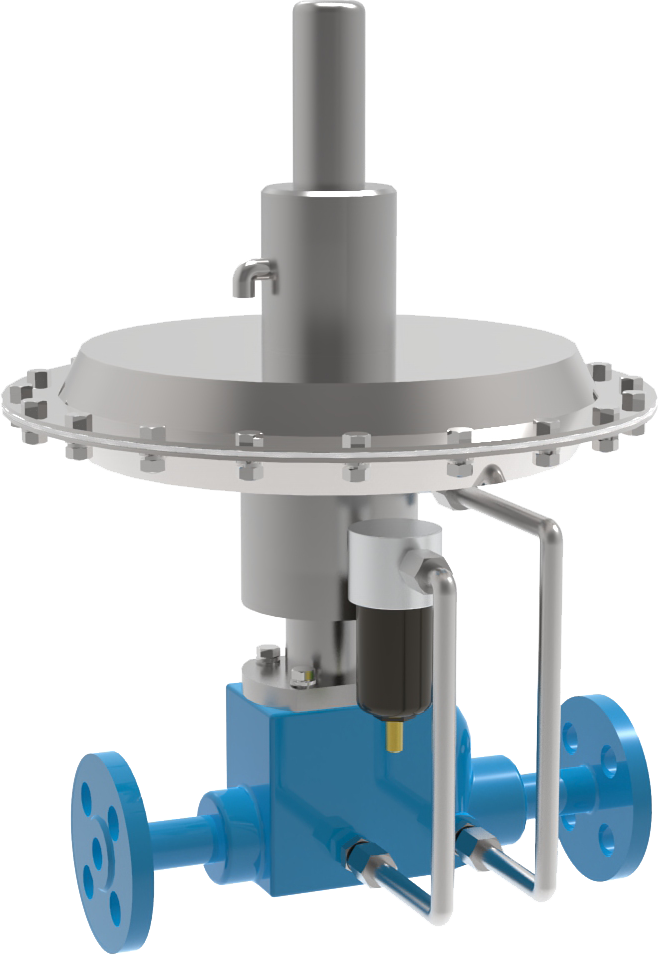

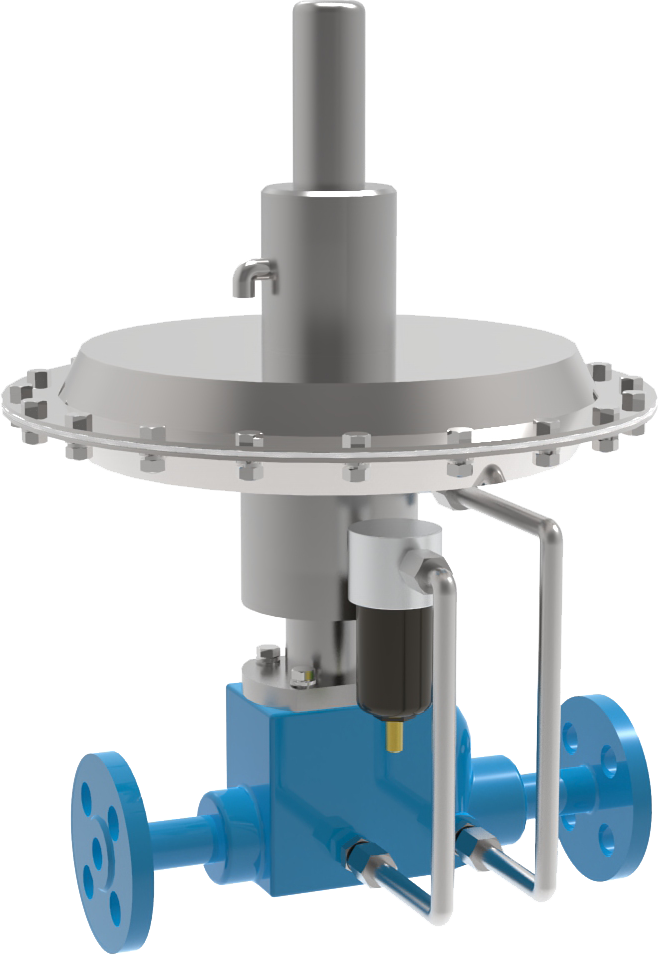

N2 Blanket gas controller helps gas pressure to maintain in constant state in the vapor space of storage Tanks. When liquid run out from storage vessel or vacuum state take place because of temperature dropping, N2 Blanket gas controller has a ability of control desired pressure within the fixed limits.

Besides above subjects, prevents air and humidity from entering into storage vessel, So it can preserve products, and also protect from a fire.

It protects the tank from explosion by restricting spark.

It prevents the outflow of fluid by evaporation

N2 Blanket gas controller helps gas pressure to maintain in constant state in the vapor space of storage Tanks. When liquid run out from storage vessel or vacuum state take place because of temperature dropping, N2 Blanket gas controller has a ability of control desired pressure within the fixed limits.

Besides above subjects, prevents air and humidity from entering into storage vessel, So it can preserve products, and also protect from a fire.

It protects the tank from explosion by restricting spark.

It prevents the outflow of fluid by evaporation

N2 Blanket gas controller helps gas pressure to maintain in constant state in the vapor space of storage Tanks. When liquid run out from storage vessel or vacuum state take place because of temperature dropping, N2 Blanket gas controller has a ability of control desired pressure within the fixed limits.

Besides above subjects, prevents air and humidity from entering into storage vessel, So it can preserve products, and also protect from a fire.

It protects the tank from explosion by restricting spark.

It prevents the outflow of fluid by evaporation

Situations that demand a Rupture Disc

• In case there is any concern that there can be an abrupt rise in pressure that cannot be endured by a spring type safety valve.

• In case there is any concern that fixtures generated by the operation state may damage the operation function of other safety materials owing to excessive pressure.

• In case the leakage of oil reserved in a tank from a safety device is not permitted during an operation.

• In case there is a need to have a protective device in preparation for a container and pipe that reserves or produces oil of a strong corrosive nature.

• In case of handling or reserving materials that are likely to undergo a synthetic reaction.

• In case there is a possibility that an excessively high or low temperature in the operational environment might inhibit the operation of a safety valve.

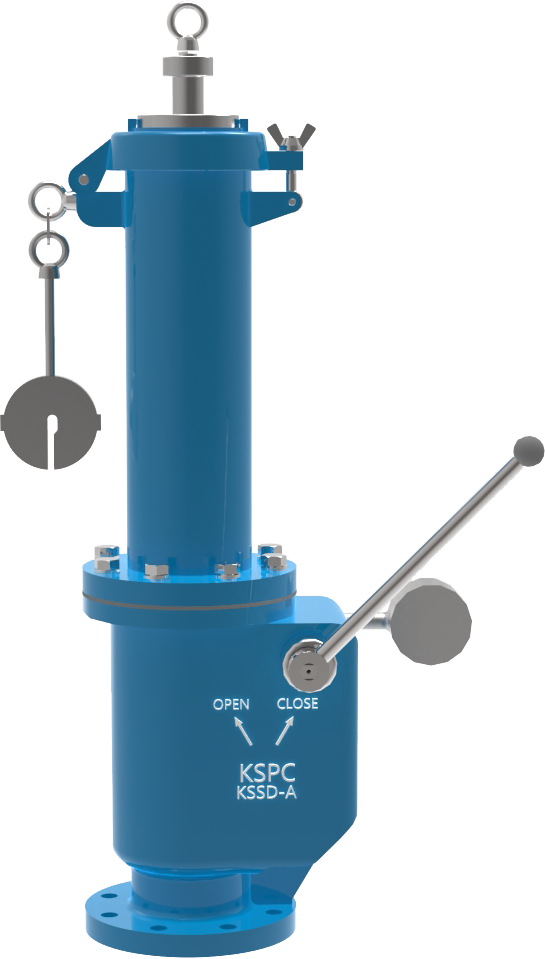

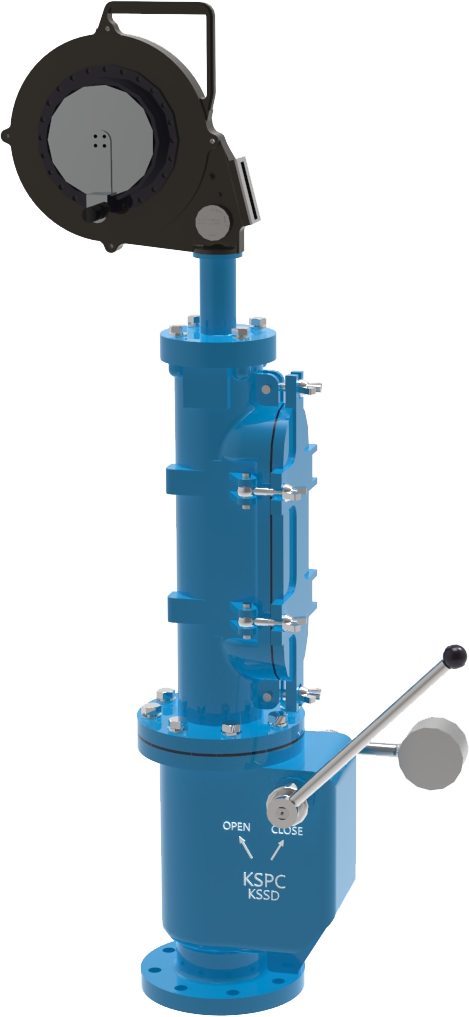

GENERAL DESCRIPTION :

Designed for gauging the height of liquid levels, measuring the depth of water bottoms, taking temperature, and taking sample of liquids held in storage tank, without relieving pressure within the tank. It avoids the loss of valuable vapors, and exposing the gauger to excessive fumes.

Quick opening valve unit is opened and closed simply by moving a lever through a 90℃ arc.

A by-pass is provided to equalize in the tank and sampling chamber unit, if this should be necessary for easy opening.

The window in the top cover of the gauging unit can be provided with an inside wiper, to insure clear vision of the gauge taper, and to permit the taking of accurate reading.reading.

INSTALLATION

1. Mount the KSSD Series Sampling Device on 4” or 8” flange roof nozzle.

2. Attach the gauging bob or sampling bottle to the swivel snap inside the sampling chamber unit.

3. Check the distance from the bottom of the bob to a point above the snap on the tape to make certain a correct reading is obtained.

GENERAL DESCRIPTION :

The KSSD Series Sampling Device is designed for gauging the height of liquid levels, measuring the depth of water bottoms, taking temperature, and taking sample of liquids held in storage tank, without relieving pressure within the tank.

It avoids the loss of valuable vapors, and exposing the gauger to excessive fumes.

Quick opening valve unit is opened and closed simply by moving a lever through a 90deg C arc.

A by-pass is provided to equalize in the tank and sampling chamber unit, if this should be necessary for easy opening.

The window in the top cover of the gauging unit can be provided with an inside wiper, to insure clear vision of the gauge taper, and to permit the taking of accurate reading.

GENERAL DESCRIPTION :

The Sampling and Gauging Hatch Cover of the Model KSGE type are designed, manufactured and tested according to the KSPC standard code.

The Model KSGH is made to take the fluid samples from the storage tank, to measure the temperature, and to take test of the stored fluids.

GENERAL DESCRIPTION :

The Sampling and Gauging Hatch Cover of the Model KSGH type are designed, manufactured and tested according to the KSPC standard code.

The Model KSGH is made to take the fluid samples from the storage tank,

to measure the temperature, and to take test of the stored fluids.

The model KSGH is used under 0.05 kg/cm2 pressure of storage tank.

According to API 2000 Code :

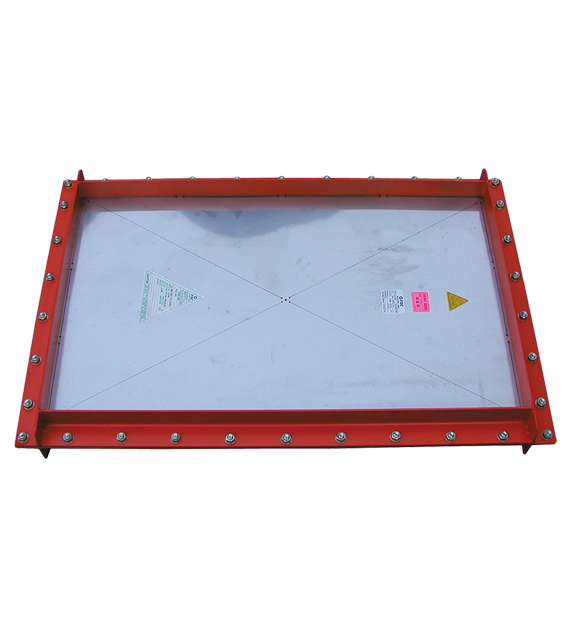

The series KSEPR/EPS is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

Vent Operation :

The KSEPR/EPS emergency pressure relief vent provides pressure relief only.

Vacuum relief must be supplied by normal venting devices, or use our KSEV emergency pressure and vacuum relief vent covers.

When excessive pressure builds within the storage tank the KSEPR/EPS emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base..

Construction :

The series KSEPR/EPS is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

The KSEPR is a weighted pallet model designed to handle pressure with a minimum pressure of 20mmW.C and a maximum setting of 700mmW.C

The KSEPS is a spring loaded model designed to handle pressure with a minimum pressure of 700mmW.C and a maximum setting of 7,000mmW.C

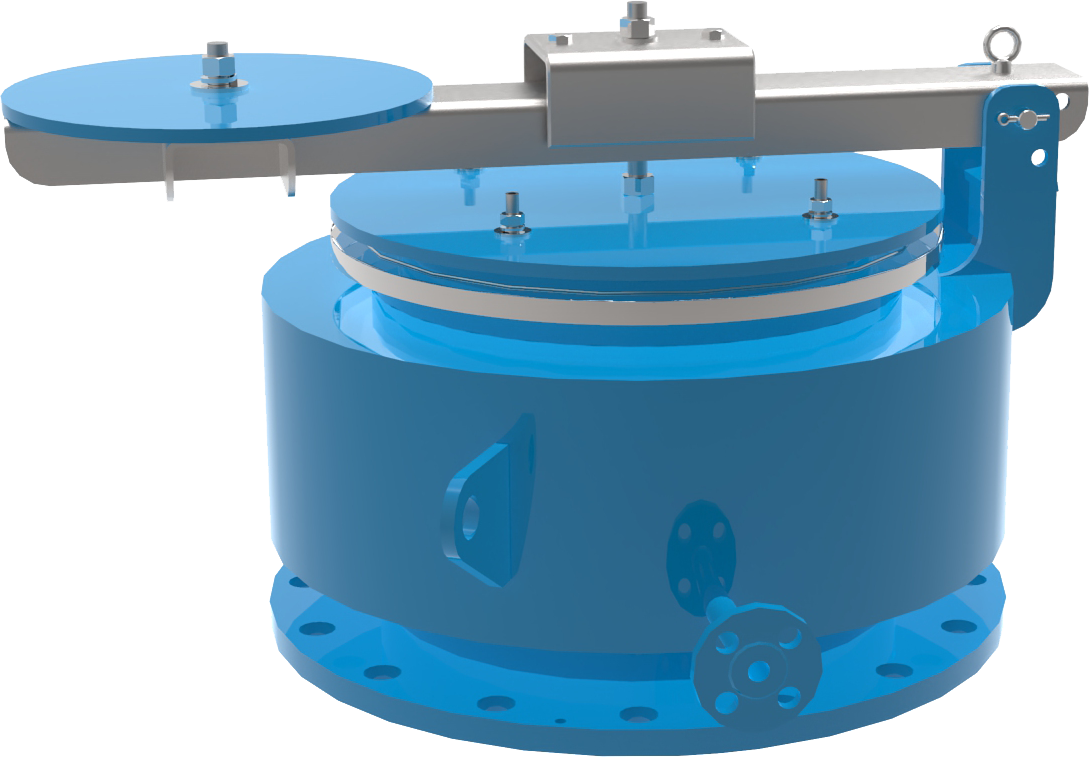

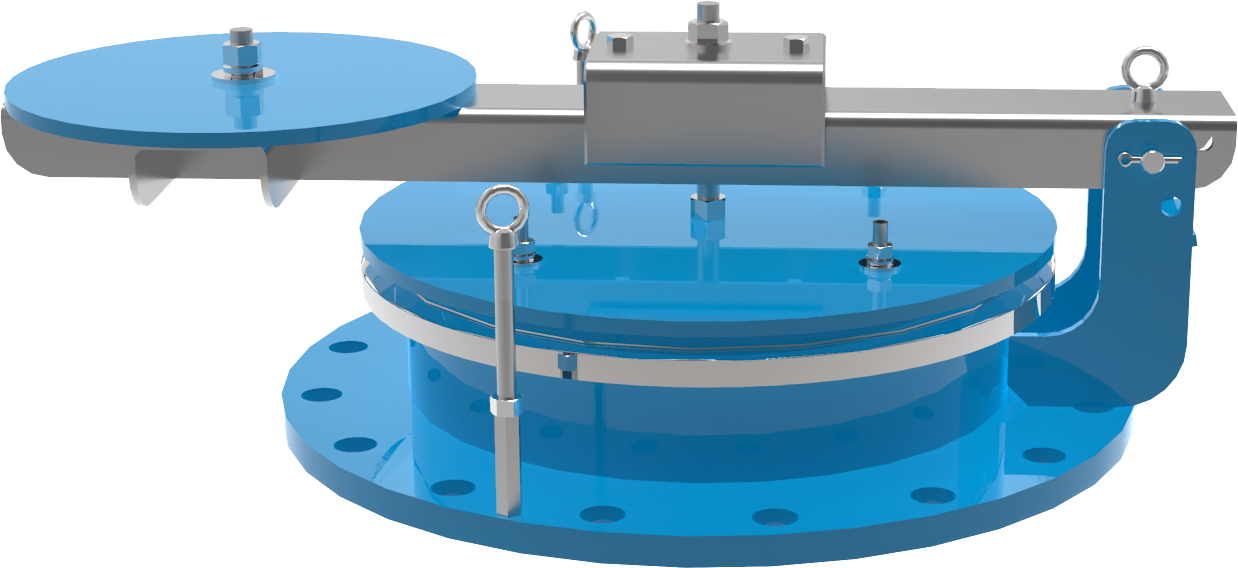

According to API 2000 Code :

The series KSEPK is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

Vent Operation :

The KSEPK emergency pressure relief vent provides pressure relief only.

Vacuum relief must be supplied by normal venting devices, or use our KSEV emergency pressure and vacuum relief vent covers.

When excessive pressure builds within the storage tank the KSEPK series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSEPK is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined setting range is from a minimum of 50mm W.C to a maximum of 700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.

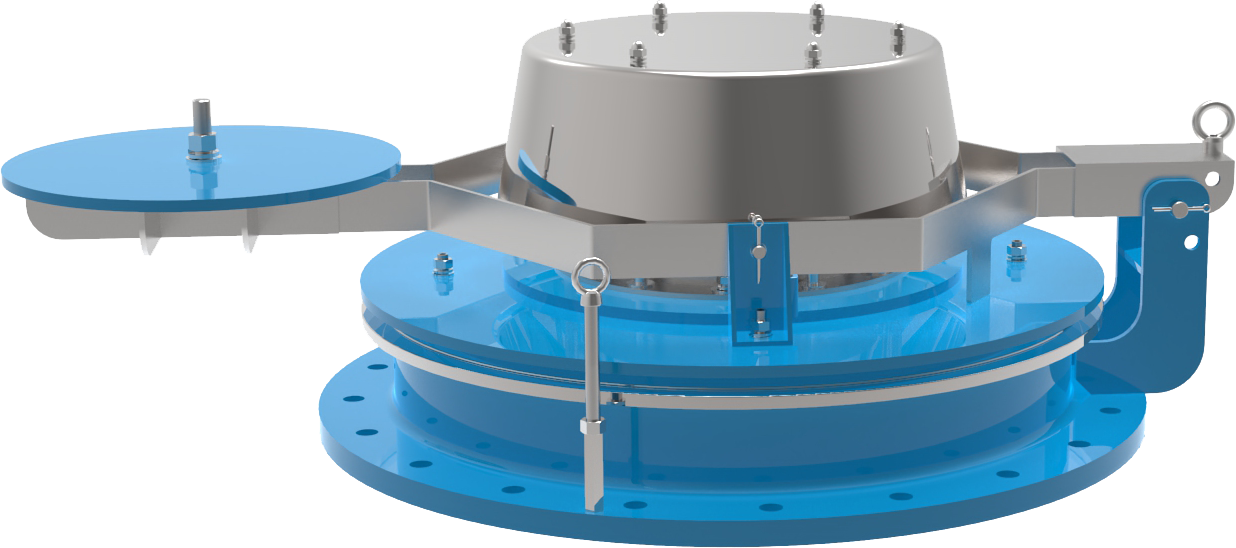

According to API 2000 Code :

The series KSEVK is designed to provide emergency pressure vacuum relief for storage tanks when exposed to over pressures and over vacuum that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

These covers can also be easily lifted open, providing a large, unobstructed passage for rapid entry and quick easy access to the tank for tank inspection and maintenance

Vent Operation :

The KSEVK emergency pressure relief vent provides pressure vacuum relief .

When excessive pressure builds within the storage tank the KSEVK series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSEVK is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined pressure / vacuum setting range is from a minimum of 25/-25mmW.C to a maximum of 700/-700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.

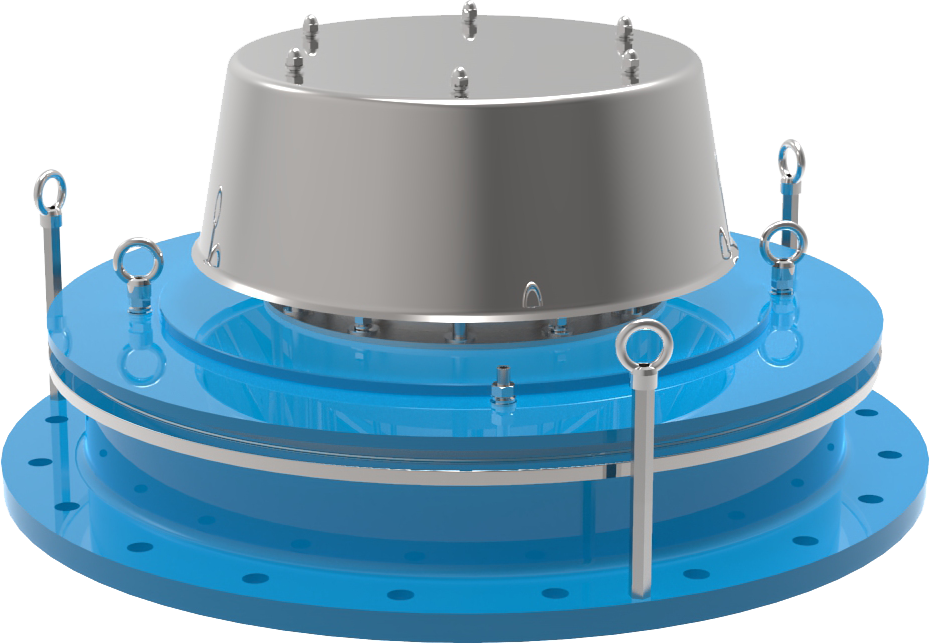

According to API 2000 Code :

The series KSEV is designed to provide emergency pressure vacuum relief for storage tanks when exposed to over pressures and over vacuum that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

Vent Operation :

The KSEV emergency pressure relief vent provides pressure vacuum relief .

When excessive pressure builds within the storage tank the KSEV series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSEV is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined pressure / vacuum setting range is from a minimum of 25/-25mmW.C to a maximum of 700/-700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.