According to API 2000 Code :

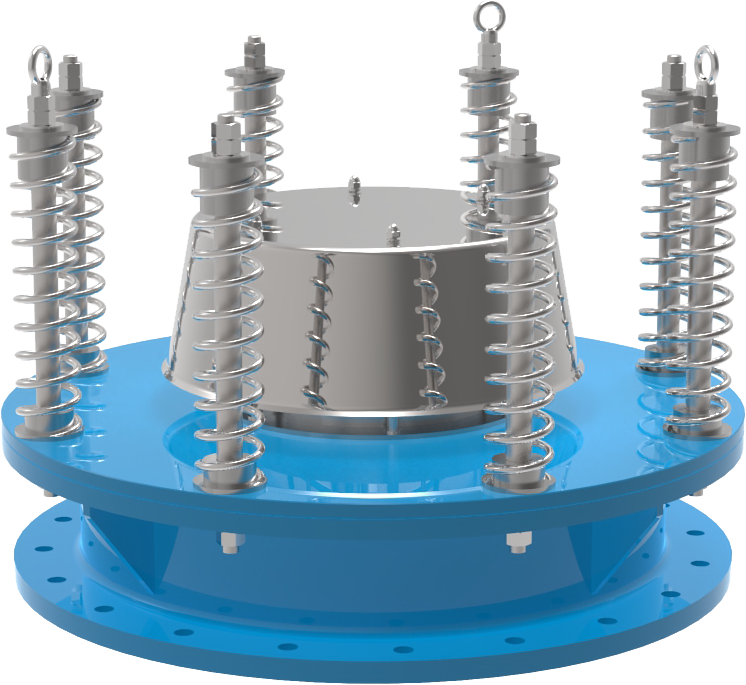

The series KSESV is designed to provide emergency pressure vacuum relief for storage tanks when exposed to overpressures and overvacuum that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

Vent Operation :

The KSES emergency pressure relief vent provides pressure and vacuum relief..

When excessive pressure builds within the storage tank the KSESV series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSESV is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined pressure setting range is from a minimum of 700mm W.C to a maximum of 7,000mmW.C and vacuum setting range is from a minimum of -20 mmW.C to maximum of

-700 mmW.C.

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650.

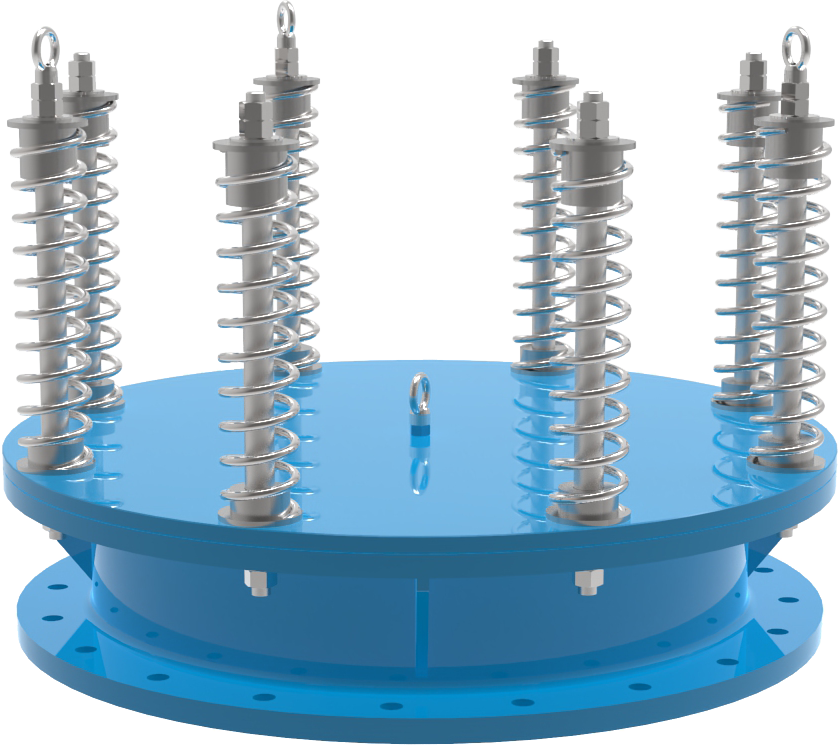

According to API 2000 Code :

The series KSES is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

Vent Operation :

The KSES emergency pressure relief vent provides pressure relief only.

Vacuum relief must be supplied by normal venting devices, or use our KSESV emergency pressure and vacuum relief vent covers.

When excessive pressure builds within the storage tank the KSES series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSES is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined setting range is from a minimum of 700mm W.C to a maximum of 7,000mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650

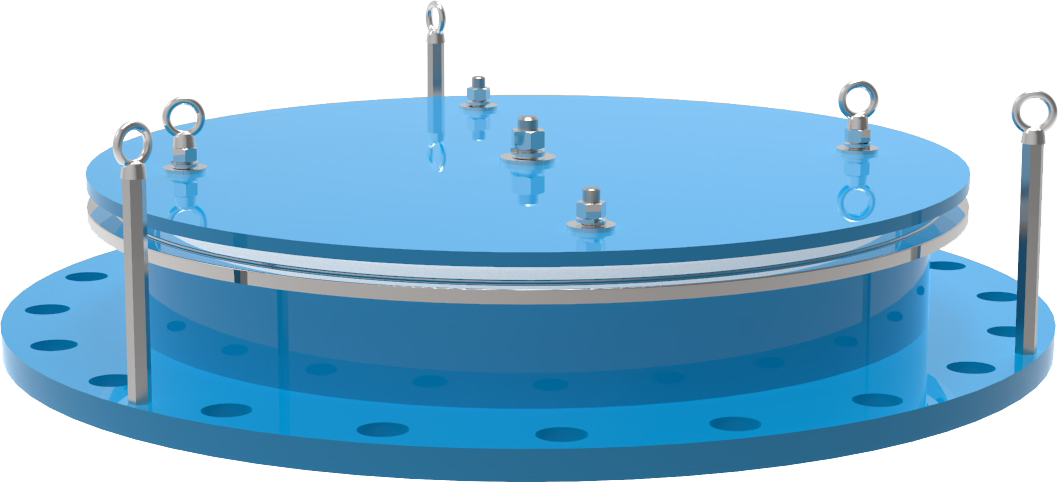

According to API 2000 Code :

The series KSEP is designed to provide emergency pressure relief for storage tanks when exposed to overpressures that are not handled by standard tank vents.

These vents provide the capacity to meet API standard 2000 for emergency venting due to fire exposure when properly sized.

These covers also provide quick easy access for tank inspection and maintenance.

Vent Operation :

The KSEP emergency pressure relief vent provides pressure relief only.

Vacuum relief must be supplied by normal venting devices, or use our KSEV emergency pressure and vacuum relief vent covers.

When excessive pressure builds within the storage tank the KSEP series emergency pressure relief vent begin to open at a predetermined set pressure relieving excessive pressure.

When the overpressure has dissipated the cover reseat onto the base.

Construction :

The series KSEP is available in several materials that are corrosion resistant to most petroleum product applications.

See Standard material of construction table for available material.

Predetermined setting range is from a minimum of 50mm W.C to a maximum of 700mmW.C

Sizes are 400, 450, 500 and 600mm with flange drilling according to ANSI 150lb or API650

Model KSBGFH /GSFH, which is used for the protector of fluid storage tank, is composed of one body with the functions of pressure relief, vacuum relief, and to block the external repellent fire.

This is consist of the flame arrester which blocks the external repellent fire, the function of discharge the overpressure developed during intake air to the storage tank, and the function of intake the air under the constant pressure during unloading. And this is the safe valve to prevent the many kinds of storage tank from the deflation (vacuum), inflation ( pressure ) and fire.

The standard flame cell is suitable for NEC group D or IEC IIA gases, Cells for other gas groups are available as additional extras.

The KSBGFH is a weighted pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of +700/-430 mmW.C

The KSGSFH is a spring loaded model designed to handle pressure and vacuum with a minimum pressure of +/-700mmW.C and a maximum setting of +/- 9,000mmW.C.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

The valves with flame arrester have additional FM factory mutual approval for the majority of sizes and materials.

Model KSBGFI /GSFI, which is used for the protector of fluid storage tank, is composed of one body with the functions of pressure relief, vacuum relief, and to block the external repellent fire.

This is consist of the flame arrester which blocks the external repellent fire, the function of discharge the overpressure developed during intake air to the storage tank, and the function of intake the air under the constant pressure during unloading. And this is the safe valve to prevent the many kinds of storage tank from the deflation (vacuum), inflation ( pressure ) and fire.

The standard flame cell is suitable for NEC group D or IEC IIA gases, Cells for other gas groups are available as additional extras.

The KSBGFI is a weighted pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of +700/-430 mmW.C

The KSGSFI is a spring loaded model designed to handle pressure and vacuum with a minimum pressure of +/-700mmW.C and a maximum setting of +/- 9,000mmW.C.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

Model KSBBFH /BSFH, which is used for the protector of fluid storage tank, is composed of one body with the functions of pressure relief, vacuum relief, and to block the external repellent fire.

This is consist of the flame arrester which blocks the external repellent fire, the function of discharge the overpressure developed during intake air to the storage tank, and the function of intake the air under the constant pressure during unloading. And this is the safe valve to prevent the many kinds of storage tank from the deflation (vacuum), inflation ( pressure ) and fire.

The standard flame cell is suitable for NEC group D or IEC IIA gases, Cells for other gas groups are available as additional extras.

The KSBBFH is a weighted pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of + 700/-430 mmW.C

The KSBSFH is a spring loaded model designed to handle pressure and vacuum with a minimum pressure of +/-700mmW.C and a maximum setting of +/- 9,000mmW.C.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

The valves with flame arrester have additional FM factory mutual approval for the majority of sizes and materials.

Model KSBBFI /BSFI, which is used for the protector of fluid storage tank, is composed of one body with the functions of pressure relief, vacuum relief, and to block the external repellent fire.

This is consist of the flame arrester which blocks the external repellent fire, the function of discharge the overpressure developed during intake air to the storage tank, and the function of intake the air under the constant pressure during unloading. And this is the safe valve to prevent the many kinds of storage tank from the deflation (vacuum), inflation ( pressure ) and fire.

The standard flame cell is suitable for NEC group D or IEC IIA gases, Cells for other gas groups are available as additional extras.

The KSBBFI is a weighted pallet model designed to handle pressure and vacuum with a minimum pressure of +/-20mmW.C and a maximum setting of + 700/-430 mmW.C

The KSBSFI is a spring loaded model designed to handle pressure and vacuum with a minimum pressure of +/-700mmW.C and a maximum setting of +/- 9,000mmW.C.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

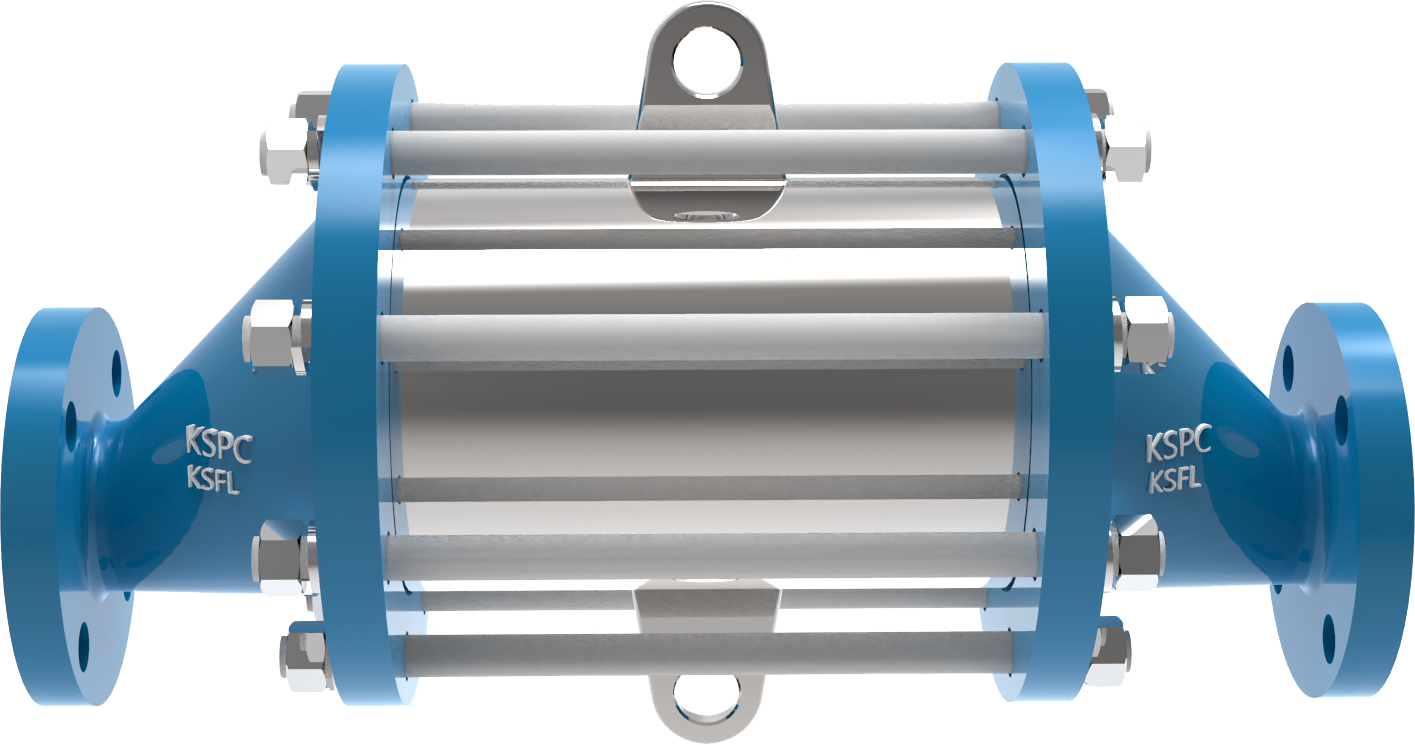

FEATURES / BENEFITS

Flame Trap A’ssy of KSPC makes no difference though it is installed in line of horizontality or perpendicularity. Fuse has an element which is made of metal, and to be melted easy. So it can intercept flame within 15 seconds at 260 deg F (=127 deg C)

You can see the position of valve disc stem at outside though heat resisting plate glass, so you can confirm whether valve is opened or closed. Also disassembly and cleaning of flame element is convenient and we can repair fast and it doesn’t need disassembly by exchange.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The KSFE unit gives the protection needed. For size 4” and under after ignition of the out flowing gases a fusible element melts, the spring loaded cover automatically opens and the full surface of the flame arrester is exposed so that the flame arrester element will not attain the ignition temperature through heat absorption.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 90 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 20” / DN 500. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

Housing construction are Aluminium, Cast Iron, Cast Steel, 304SS, and 316LSS. Hood construction is stainless steel and the element is 316LSS.

Sizes are from 20mm through to 500mm.

Cast iron and cast steel units are epoxy coated both inside and outside.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 90 deg C / 140 deg F and Maximum allowable operating pressure up to 1.2 bar abs from size ½” / 15A to 6” / DN 150 and up to 1.1 bar abs from size 8” / DN200 to 16” / DN 400. Upon request, it can be obtained for higher pressure and higher temperatrue with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 15mm to 300mm as Standard and upon request, it can be obtained for higher size.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The standard flame cell is suitable for NEC group D or IEC IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The flame arresters are available with either carbon steel (epoxy coated), 304SS, or 316SS housing with 316LSS flame cells.

Sizes range from 25mm to 600mm.

Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The model KSFL Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element.

This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFL flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size 2” / 50A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SS, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 25mm to 600mm. Standard flanges are ANSI 150lb and other connections & size are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

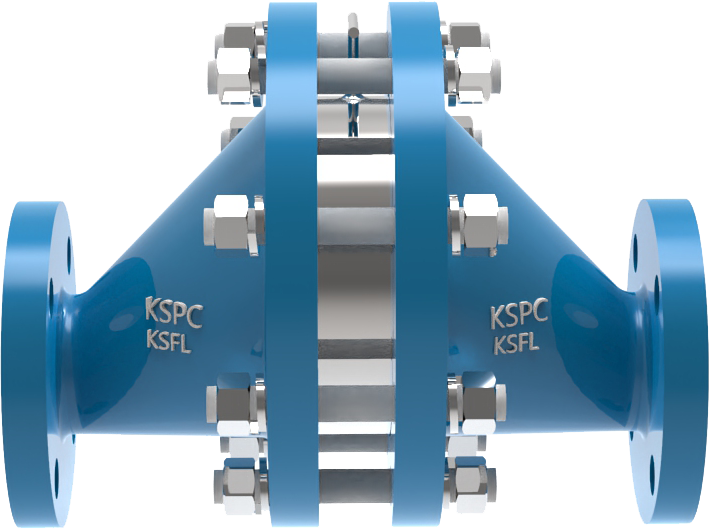

The model KSFH Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

Additionally All most of size shall be approved FM (Factory Mutual).

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element.

This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFH flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either vertically or horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size 2” / 50A to 12” / DN 300.

Upon request, it can be obtained for higher pressure and higher temperature with special approval

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SSss, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 50mm to 300mm. Standard flanges are ANSI 150lb and other connections are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

The model KSFI Inline Flame Arrester is designed, manufactured, tested according to API 2000, British Standard Specification Code BS7244, and EN 12874 / ISO 16852.

The units are passive devices with no moving parts.

They prevent the propagation of flame from the exposed side of the unit to the protected side by the use of a 316L stainless steel crimped metal ribbon type flame cell element. This construction produces a matrix of uniform opening that are carefully constructed to quench the flame by absorbing the heat.

This provides an extinguishing barrier to the ignited vapor mixture.

The KSFI flame arrestors have specifically designed heat transfer characteristics for slow moving flames and low to medium pressure fronts (low to medium deflagration).

Inline flame arresters can be installed either vertically or horizontally within a designated distance from the potential ignition extras.

The standard flame cell is suitable for NEC group D or IEA IIA gases. Cells for other gas groups are available as additional extras.

The standard design shall be used up to an operating temperature of + 60 deg C / 140 deg F and operating pressure up to 1.1 bar abs from size ½” / 15A to 12” / DN 300. Upon request, it can be obtained for higher pressure and higher temperature with special approval.

The fame arresters are available with either aluminum, nodular iron, cast steel, 304SS, 316SS and 316LSS housings. Iron and steel housings are supplied epoxy coated.

Sizes range from 15mm to 600mm and available upon request. Standard flanges are ANSI 150lb and other connections and size are available upon request.

MAINTENANCE

Periodic inspection and maintenance is required. The cell assembly can be removed for cleaning purposes. Cleaning ban be accomplished by dipping the entire cell assembly into an appropriate solvent. Care should be taken not to damage the cell openings as such deformations hamper the flow through the cell. The gaskets should be inspected and replaced if necessary.

Designed to release accumulated air pockets from the system, while pressured pipeline, Air Pockets Increase energy consumption because pumping operation will be at higher water heads to overcome Pressured air.

KSBJ has function to protect high shock and surge pressure, water hammer and liquid Overflow from fresh or sea water pipelines.

KSBJ air release valve can provide low cast insurance to protect expensive maintenance cost of Pipelines and pump systems.

Designed manufactured and tested according to the API 2000 code.

Utilize the latest technologies to provide protection against positive or vacuum over pressure and prevent air intake, evaporative losses of product and help to contain odorous and potentially explosive vapours.

The KSVB is a spring loaded model, designed to handle under pressure with a minimum pressure of -25 mmW.C and a maximum setting of -9,000 mmW.C.

Body materials are available in Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

Designed manufactured and tested according to the API 2000 code.

Utilize the latest technologies to provide protection against positive or vacuum over pressure and prevent air intake, evaporative losses of product and help to contain odorous and potentially explosive vapours.

The KSVR is a weighted pallet model, designed to handle under pressure with a minimum pressure of -20mmW.C and a maximum setting of -430mmW.C

The KSVS is a spring loaded model, designed to handle under pressure with a minimum pressure of -430mmW.C and a maximum setting of -9,000mmW.C.

Body materials are available in Aluminium, Carbon Steel, 304SS and 316SS with various trims to suit individual requirements.

Sizes range from 50mm through to 350mm with ANSI 150lb flanges as standard.

(Different connections available on request).

The model KSBD and KSDS pressure vacuum valves are an advanced design for pipe away applications.

Designed manufactured and tested according to the API 2000 code.

Utilize the latest technologies to provide protection against positive or vacuum over pressure and prevent air intake, evaporative losses of product and help to contain odorous and potentially explosive vapours